Are you experiencing issues with your chimney liner? If yes, you might ask yourself, can a chimney liner be repaired? The short answer is yes. Chimney liners can be repaired in most cases.

However, the feasibility of repair depends on the type of liner, the extent of damage, and the specific circumstances. Understanding the parts of a chimney can help homeowners be better informed about potential problems.

This makes it crucial to have a professional chimney sweep installer assess the liner’s condition and recommend the appropriate course of action.

In this article, we share our expertise and experience in chimney repairs. We also share the benefits and the most effective chimney liner repair option to help you restore the functionality and safety of your chimney system.

Can a Chimney Liner Be Repaired?

Chimney liners can be repaired in many cases, depending on the type of liner, the number of damaged tiles, the location of the cracks, and the type of chimney you have. Understanding common chimney liner problems is essential to diagnosing the right solution

While some liner issues may require a complete replacement, there are situations where a repair project is a viable and cost-effective solution.

Here are a few scenarios to help you determine if your chimney liner requires repair or replacement:

- Minor Cracks or Damage: If your chimney liner has minor cracks, gaps, or localized damage, it can often be repaired. This job typically involves patching the damaged areas by adding a chimney cement mortar to the exposed joints.

- Single Broken Tile: If there is only one broken tile in the chimney liner and it is accessible enough for replacement, it can be replaced individually. This is a more affordable and less invasive solution than a full replacement.

- Extensive Damage or Deterioration: In cases where your chimney liner has extensive damage or deterioration, like significant cracks, crumbling, or corrosion, replacement may be necessary. If the liner is compromised to the extent that it cannot adequately contain the byproducts of combustion or poses safety risks, it is recommended to replace it entirely.

- Unsuitable Liner Type: In some instances, the existing chimney liner may be incompatible with the fuel used. For example, a clay tile liner may not be suitable for high-efficiency appliances or certain fuels. Replacing the liner with one specifically designed for the intended use may be necessary.

- Age and Condition: If your liner is nearing the end of its expected lifespan or shows signs of significant deterioration, replacement may be the most practical solution. Older liners may not meet current safety standards or provide optimal performance, making replacement a wise choice.

——

Do You Need to Hire Chimney & Fireplace Expert?

Get free quotes from qualified experts near you. No commitment required!

——

Why Are Chimney Liners Important?

Although often overlooked, chimney liners play a critical role in the chimney system.

Not only do they help maintain its structural integrity, but they also safeguard your home from a potential chimney fire and prevent toxic gases from entering your home.

Below are more reasons why having a functional chimney liner in your home is important:

1. Safety Reasons

Chimney Fact: Did you know combustibles can start a house fire in an unlined chimney in less than 3.5 hours of use?

Chimney liners act as a barrier, preventing house fires and protecting your home and family. Without a liner, the intense heat produced during combustion transfers to the surrounding structure, increasing the risk of igniting items nearby, such as creosote, soot, and debris.

Moreover, a properly installed and maintained chimney liner helps prevent toxic gases like carbon monoxide from seeping into your home. It ensures that these dangerous gases are safely expelled through the chimney, keeping your home’s indoor air quality safe.

2. Efficiency Reasons

The efficiency rating for a well-functioning chimney liner can range from 70% to 99%. This high efficiency is achieved by effectively containing and directing flue gases, optimizing combustion, and minimizing heat loss.

In contrast, a poorly functioning or damaged chimney liner can significantly reduce efficiency, leading to lower combustion temperatures, increased heat loss, and potential backdraft issues, resulting in efficiency ratings dropping to as low as 10% to 40%.

Furthermore, chimney liners help prevent the buildup of creosote that is formed and deposited on the chimney’s inner walls due to incomplete combustion. A properly installed and insulated chimney liner creates a smooth surface, reducing the chances of creosote sticking to the walls.

3. Increases the Chimney’s Lifespan

Chimney liners provide additional protection for the chimney walls, shielding them from the corrosive effects of combustion byproducts. This helps prevent the deterioration of the chimney structure over time.

As a result, your chimney gets an extended life and reduces the need for costly repair or replacement.

What Are The Benefits of Chimney Liners?

The benefits of chimney liner repair, whether through HeatShield or other repair methods, are numerous. They include:

- Increased Safety: A damaged or deteriorated chimney liner poses serious safety risks by allowing heat transfer to combustible materials around your home, increasing the chance of a house fire. For instance, the United States experiences over 25,000 chimney fires per year, causing more than $125 million in property damage, with defects in chimney linings being a significant contributing factor. However, repairing the chimney liner enhances your home’s safety, preventing these potential hazards.

- Cost-effective Solution: Repairing a chimney liner is often more cost-effective than a complete replacement. Repairs can also be targeted to areas of concern, saving you from the expense of replacing the entire liner. Repairing minor cracks or damage might cost you between $75 to $150 per square foot. But replacing the same would cost you around $2,300 to $7,500. Get several quotes and information from chimney contractors to help you determine the best option.

- Extended Chimney Lifespan: By restoring the liner’s integrity and functionality, you enhance its ability to withstand the corrosive effects of combustion byproducts. This not only improves the safety and efficiency of the chimney but also reduces the need for premature replacement, saving you money in the long run.

- Improved Efficiency and Chimney Performance: A damaged chimney liner impedes proper draft and hinders the efficient operation of your fireplace. By repairing the liner, you restore optimal airflow and draft, enhancing the overall performance of your chimney system. This results in improved combustion, better heat output, and a more enjoyable and efficient heating experience.

Types of Chimney Liners

There are various types of chimney liners available with unique characteristics and benefits. Here are some of the most common chimney liners:

- Clay Tiles: Clay flue liners are commonly used in masonry chimneys. They are durable, heat-resistant, and offer excellent insulation. However, they may crack or deteriorate over time, requiring maintenance or replacement.

- Metal Liners: Metal chimney liners like flexible stainless steel or aluminum are suitable for masonry and prefabricated chimneys. They are highly durable, resistant to corrosion, and provide efficient venting. Metal liners are often used in retrofitting or relining when other liner options are not feasible.

- Cast-in-Place Liners: This type involves applying a cement-like mixture directly onto the chimney walls. It creates a custom-fitted, seamless liner that offers excellent insulation and durability. Homeowners often turn to cast-in-place liners for older chimneys or when existing liners need restoration.

——

Do You Need to Hire Chimney & Fireplace Expert?

Get free quotes from qualified experts near you. No commitment required!

——

What Is HeatShield and Its Role in Chimney Liner Repair?

HeatShield is a chimney liner repair system that consists of a Cerfractory sealant, which combines ceramic and refractory properties. This blend provides insulation, durability, and resistance to heat and chemicals in the chimney.

HeatShield is a specially formulated chimney repair system that can restore the integrity and functionality of damaged liners. Below are its roles in chimney liner repair:

- Resurfacing: HeatShield is used to resurface the interior of the damaged chimney liner, creating a smooth and durable surface. It fills in cracks, gaps, and voids, restoring the liner’s structural integrity and preventing further deterioration.

- Sealing: The application of HeatShield creates an airtight seal, preventing the escape of combustion byproducts, like smoke, harmful gases, and sparks, into the surrounding chimney structure and living spaces of homes. This ensures the safe and efficient operation of the chimney system.

- Insulating: HeatShield provides insulation properties, reducing heat transfer from the flue to the masonry or adjacent combustible materials. This helps protect the chimney structure and minimizes the risk of heat-related damage or ignition of surrounding materials.

The Process of Chimney Liner Repair with HeatShield

HeatShield fills in cracks, gaps, and voids within the chimney liner. Once applied, HeatShield cures and hardens, forming a strong and durable barrier that resists high temperatures and the corrosive effects of combustion byproducts. This restores the liner’s integrity by ensuring it functions effectively and optimally.

Heatshield Repair Process for Clay and Stainless Steel

The repair process for chimney liners using HeatShield varies depending on the type of liner. Therefore, you’ll need the help and expertise of trained professionals experienced in using HeatShield and performing chimney liner repairs to assist you with the correct and most effective process. Contact a chimney repair business with any questions you might have.

That said, here’s an overview of what to expect during the HeatShield repair process for clay and stainless steel:

1. Inspection: The professional chimney contractor carefully inspects the liner for any cracks, gaps, or other damage that needs to be repaired. While the base and outdoor inspections are crucial, using a chimney inspection camera to access the interior will help analyze damage inside the chimney liner.

2. Cleaning: The technician thoroughly cleans the interior surface of the liner to remove debris, soot, or creosote buildup, which causes blockage. A wire brush should suffice to remove the rust or scale from the surface of a stainless steel liner that has gathered rust.

3. Foam Plug Installation: The chimney foam applicator plug is inserted into the flue opening and positioned to block off the bottom of the chimney.

4. HeatShield Mixture Preparation: The HeatShield product is prepared according to the manufacturer’s instructions. This typically involves mixing the HeatShield powder with a liquid activator.

5. Application: The prepared HeatShield mixture is poured or sprayed around the foam plug, starting at the bottom and working upward. The technician ensures that the mixture completely covers the damaged areas of the liner.

6. Resurfacing and Smoothing: The technician uses specialized tools to smooth the applied HeatShield mixture, ensuring an even and uniform surface. Any excess material is removed.

7. Curing: The HeatShield repair compound is left to cure and harden, typically for a specific period, as the manufacturer recommends.

8. Final Inspection: Once the HeatShield repair has cured, the service technician inspects the repaired liner using a chimney inspection camera to ensure the integrity of the repair and that the liner’s functionality is restored.

How Do I Know if My Chimney Liner Needs Replacing?

The average lifespan of a chimney liner is around 15 to 20 years, but this will depend on usage and maintenance. However, they can become damaged due to age, weather conditions, or improper installation.

Here are some indicators that your chimney liner may require replacement:

- Visible cracks or gaps in the liner: Inspect the interior of your chimney for any visible cracks or gaps in the liner. These openings can allow gases, smoke, and heat to escape, compromising the safety and efficiency of your chimney.

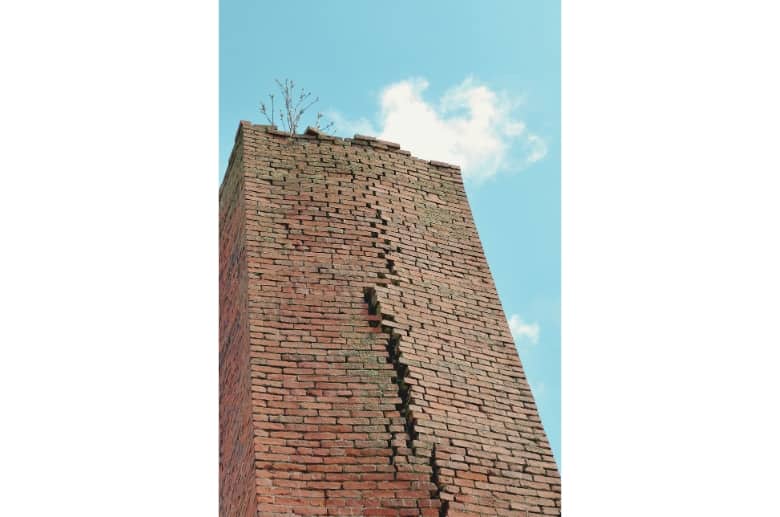

- Deterioration of mortar joints: If you have a masonry chimney, check for deteriorating joints between the flue tiles or bricks. Crumbling or missing mortar can indicate liner damage and the need for replacement.

- Spalling or flaking off clay flue tiles: Clay flue tiles can deteriorate over time, especially if exposed to excessive heat or moisture. Look for signs of spalling or flaking off of the clay tiles, as this can compromise the structural integrity of the liner.

- Issues with fireplace performance: If you experience problems with your fireplace, such as difficulty lighting fires, keeping the fire burning, excess smoke, or poor draft, it could be a sign of a damaged or inadequate chimney liner. Having it checked out and replaced should easily solve these problems.

- Water damage: Water intrusion into your chimney can lead to liner deterioration. Inspect for signs of water damage, such as rusting of metal components, staining on the chimney walls, or mold or mildew. If you notice any of these signs, you must replace your liner immediately.

——

Do You Need to Hire Chimney & Fireplace Expert?

Get free quotes from qualified experts near you. No commitment required!

——

Chimney Liner Repair Cost

The cost of chimney liner repair can vary depending on the extent and type of repairs needed. Below is a general breakdown of the cost range for different types of chimney liner repairs:

Minor Repairs:

- Minor cracks, gaps, or localized damage: $200 to $500

- Chimney cement mortar application: $150 to $300

Single Broken Tile:

- Replacement of a single broken tile: $150 to $250

Extensive Repairs:

- Extensive damage requiring partial liner replacement: $500 to $1,500

- Resurfacing damaged liner with a specialized coating: $800 to $1,500

For severe damage that cannot be repaired, a full chimney liner replacement may be necessary. The cost for this can range from $2,500 to $5,000 or more, depending on the liner type and size of the chimney.

However, the actual cost can vary depending on factors like:

- Type of Liner: Different liners, such as clay, metal, or cast-in-place, have varying material and installation costs.

- Size of Your Chimney: Larger chimneys require more materials and labor, which can increase the overall cost of the repair.

- Number of Appliances Using the Chimney Flue: If you have multiple appliances, such as furnaces or fireplaces, connected to the chimney flue, the repair cost may be higher.

- Condition of the Chimney: If your chimney has extensive damage or requires significant repairs before installing a new liner, it can increase the overall cost.

- Need for Additional Services: Additional services, like chimney inspection and cleaning, can add to the repair cost.

- Cost of Permits: The cost of obtaining permits can vary and should be considered when estimating the overall repair cost.

Stainless Steel Chimney Liner Repair Costs

A stainless steel chimney liner repair ranges from $200 to $3,000. This cost covers the materials, labor for installation, and any necessary fittings, products, or accessories.

However, this cost can vary depending on the liner’s length and diameter, the installation’s complexity, and the additional components or services required.

Cast-In-Place Liner Repair Costs

Repairing a cast-in-place liner involves addressing any cracks, gaps, or deterioration in the liner’s structure. You can expect to part ways with between $500 to $2,800 for this type of liner.

Again, the actual cost will vary depending on the extent of damage, the size of the chimney, and the complexity of the repair.

Clay Flue Liner Repair Costs

Generally, clay flue liner repair can range from $500 to $2,500. However, minor repairs, like patching small cracks or applying a sealant, will typically be on the lower end of the price range.

Additionally, the cost can be higher if the damage is extensive and requires significant repairs or even a complete replacement of the flue liner. Request an estimate from a chimney contractor to determine what you might have to pay.

| Chimney Liner Type | Repair Cost |

| Stainless steel chimney liner | $200 to $3,000 |

| Cast-in-place chimney liner | $500 to $2,800 |

| Clay flue chimney liner | $500 to $2,500 |

Conclusion

Maintaining a functional chimney liner is crucial for safety and efficiency. It ensures the safe removal of combustion byproducts and prevents heat transfer to combustible materials.

We highly recommend seeking professionals from a reputable company to help with inspection, repair, and maintenance. Professionals can accurately assess the liner’s condition, detect issues early, such as gas leaks, and provide necessary repairs.

If you suspect any problem with your chimney liner, contact us today! We have chimney repair specialists for thorough inspections and proactive maintenance.