A chimney liner is an integral component that lines the inside of your chimney, protecting it from the intense heat, corrosive byproducts, and potential hazards caused by smoke and combustion gases.

However, not all chimney liners are created equal. There exists a crucial distinction between insulated vs non-insulated chimney liners that can significantly impact the performance and safety of your chimney system.

Understanding the difference between the types of chimney liners is essential. It can mean the difference between a warm and cozy home or a potential fire hazard lurking above your living space.

In this comprehensive comparison guide, we will explore the intricacies of these chimney liners, highlighting their characteristics, benefits, and why choosing the right one for your specific needs is imperative.

What Is an Insulated Chimney Liner?

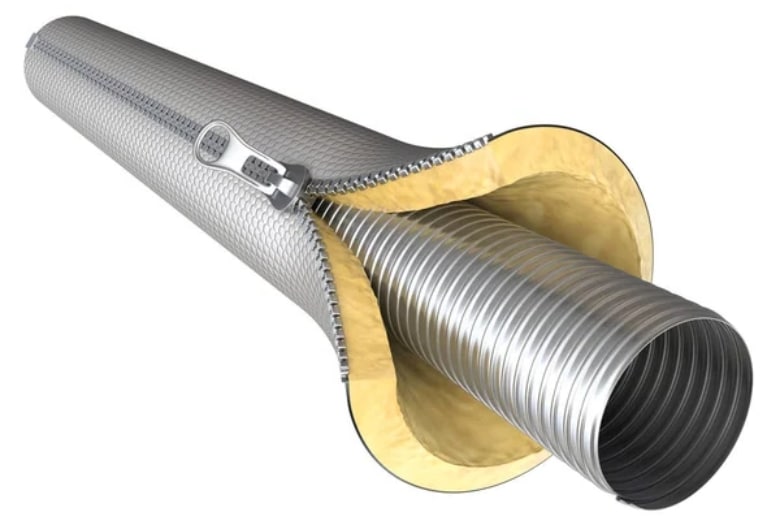

An insulated chimney liner is a lining system incorporating an additional insulation layer around the inner liner. This type of chimney liner typically includes main liner materials such as clay or flexible stainless steel. On the other hand, the insulation layer can be made of high-temperature-resistant materials like ceramic fiber or mineral wool.

Insulated chimney liners have been proven to enhance draft efficiency compared to non-insulated counterparts. Draft efficiency refers to the ability of chimneys to create a consistent and reliable upward flow of air out of your house.

Studies have shown that insulated chimney liners can improve draft efficiency by up to 20%. This increased efficiency ensures more efficient removal of smoke and combustion byproducts, resulting in better overall fireplace or stove performance.

Insulation in chimney liners serves multiple purposes.

- Firstly, it helps to keep the temperature of the flue gases warmer as they rise through the chimney. This prevents the gases from cooling too quickly and potentially causing condensation, which can lead to the formation of creosote—a highly flammable substance that increases the risk of chimney fires.

- Secondly, insulation minimizes heat transfer to the masonry or surrounding combustible materials, reducing the chances of structural damage or the ignition of nearby objects.

——

Do You Need to Hire Chimney & Fireplace Expert?

Get free quotes from qualified experts near you. No commitment required!

——

Type Of Chimney Liner Insulations

Chimney liner insulation plays a crucial role in enhancing the performance and safety of a chimney system. Several types of chimney liner insulation are available, each with unique characteristics and benefits. Let’s explore the different types and their specific features:

Pre-Insulated Liner

A pre-insulated liner refers to a chimney liner with insulation material already attached to the liner. This insulation is typically made of a high-temperature-resistant material such as ceramic fiber or mineral wool.

It offers excellent thermal insulation properties, helping to retain heat within the chimney and preventing the formation of condensation. Some popular brands that offer pre-insulated chimney liners include TherMix, Chimwrap, and Selkirk.

Blanket Wrap Insulation

Blanket wrap insulation involves wrapping an insulation material around the chimney liner, such as ceramic fiber or mineral wool. It provides a layer of thermal insulation, reducing heat loss and improving the overall efficiency of the chimney system.

Rockwool is a well-known brand that manufactures blanket wrap insulation for chimney liners. It is important to ensure the blanket wrap insulation is securely fastened to the liner to prevent sagging or movement.

Vermiculite Pour Down Mixture

Vermiculite chimney insulation is a mixture of vermiculite and cement poured around the chimney liner. Vermiculite is a lightweight, fire-resistant mineral that expands when heated, creating an insulating barrier.

This method is commonly used in older chimneys or those with irregular shapes. Vermiculite pour-down mixtures, including vermiculite material and cement binder, are often available as kits.

Snap Wrap Insulation

Snap wrap insulation involves attaching insulated panels or sections around the chimney liner. These panels are made of high-temperature-resistant materials and are secured using clips or snaps.

Snap wrap insulation provides effective thermal insulation and is relatively easy to install. Popular brands like Thermix and Selkirk offer snap wrap insulation options for chimney liners.

Regardless of the type of insulation chosen, it is important to prioritize fireproof chimney insulation. This ensures that the insulation materials can withstand high temperatures and reduce the risk of fire hazards within the chimney system.

It is advisable to select insulation materials from reputable brands like Thermix, Selkirk, and Rockwool, which specialize in manufacturing high-quality, fireproof chimney insulation products.

Advantages of an Insulated Chimney Liner

Besides the obvious safety and performance benefits, insulated chimney liners boast several noteworthy advantages.

- Improved Safety: Insulated chimney liners offer enhanced safety benefits. The insulation layer helps to maintain optimal flue gas temperatures, reducing the likelihood of creosote buildup. Creosote is a highly flammable substance that can accumulate in the chimney, posing a significant fire hazard.

- Energy Efficiency: The additional insulation helps maintain the flue gases’ warmth as they ascend through the chimney. This improves draft efficiency, allowing for a more reliable and consistent upward flow of air. With a better draft, your heating system operates more efficiently, maximizing heat output and ensuring that smoke and combustion byproducts are effectively expelled from your home.

- Longer Lifespan: The insulation layer acts as a protective barrier, reducing the exposure of the inner liner to the corrosive effects of flue gases. This resistance to corrosion helps prolong the chimney liner’s lifespan, reducing the need for frequent replacements. Additionally, the insulation layer provides added durability, reducing wear and tear over time.

- Blocking Acoustic Pollution: The insulation layer helps reduce the noise a chimney produces. This is especially beneficial for homeowners in urban environments, as it helps block any excess sound created by the burning process that may be heard outside your home.

——

Do You Need to Hire Chimney & Fireplace Expert?

Get free quotes from qualified experts near you. No commitment required!

——

Drawbacks of Insulated Chimney Liners

While insulated chimney liners have numerous advantages, certain drawbacks come with opting for an insulated system.

- More Expensive: The additional insulation material and construction complexity contribute to the increased price. However, it’s important to consider the long-term benefits, such as improved safety and performance, when evaluating the overall value of an insulated chimney liner. If you want to know what you’re looking at in terms of cost, get a solid estimate from a chimney service company.

The added safety, improved performance, and extended lifespan offered by insulated chimney liners can often outweigh the upfront expense, making them a worthwhile investment for those seeking a reliable and efficient heating system.

What Is a Non-Insulated Chimney Liner?

A non-insulated chimney liner is a basic lining system composed of a single inner liner, usually clay or flexible stainless steel. Non-insulated liners lack the insulation layer in insulated models, making them more versatile and suitable for certain applications where an insulated system is unnecessary or desired.

Without the additional insulation layer, non-insulated chimney liners are more cost-effective and easier to install. Because they lack the insulation layer, these systems are lighter and simpler to install, making them a popular choice for DIY enthusiasts. It’s a project that requires little experience and does not require a professional contractor to help you.

However, these chimney liners are known to be less efficient compared to their insulated counterparts. This lower efficiency can result in decreased draft performance and less effective removal of smoke and byproducts of combustion from your fireplace or stove.

The operation of a non-insulated chimney liner is relatively straightforward. The liner serves as a protective barrier, preventing the combustion gases from penetrating the surrounding masonry or other combustible materials.

While it fulfills this basic function, the absence of insulation means that the liner is more susceptible to the fluctuating temperatures of the flue gases. This can lead to faster cooling of the gases, increased condensation, and potential problems associated with creosote buildup.

Advantages of a Non-Insulated Chimney Liner

Similar to insulated chimney liners, non-insulated systems offer several unique advantages.

- Lower Upfront Cost: The simplicity of the design and lack of insulation material makes these systems more cost-effective than their insulated counterparts.

- Suitable for Certain Types of Fireplaces and Stoves: Non-insulated chimney liners can be suitable for specific fireplaces and stoves. For instance, if you have a gas fireplace or a modern, high-efficiency wood-burning stove that operates at lower flue gas temperatures, a non-insulated liner may be sufficient to meet the requirements of your heating system.

Drawbacks of Non-Insulated Chimney Liners

Despite cost savings and increased compatibility with certain fireplaces, non-insulated chimney liners have several notable drawbacks.

- Less Efficient: Without the added insulation, the flue gases cool down more quickly, potentially leading to condensation, creosote buildup, and reduced draft efficiency. This decreased efficiency can result in poor performance, inadequate heat output, and diminished overall fireplace or stove effectiveness.

- Higher Risk of Chimney Fires: Condensation and creosote formation are more likely to occur due to the fast cooling of flue gases, which can be highly flammable. The accumulation of creosote on the inner surface of the chimney liner also poses a significant fire hazard. This can lead to safety issues and extensive repairs.

- Shorter Lifespan: Exposure to fluctuating temperatures and potential condensation can lead to damage over time, such as accelerated corrosion and liner deterioration. This may necessitate frequent maintenance and replacement, resulting in higher long-term costs.

Insulated vs Non-Insulated Chimney Liners Comparison

To make an informed decision between an insulated and non-insulated chimney liner, it’s crucial to understand their key differences in all areas, as outlined below.

| Features | Insulated Chimney Liners | Non-insulated Chimney Liners |

| Material Durability | Stainless steel, thicker design | Clay tiles |

| Cost | About $500 to $5,000 for installation, but you enjoy lower long-term maintenance costs | Lower initial cost, potentially higher long-term costs |

| Heat Efficiency | Improved draft, better heat efficiency | Less efficient |

| Safety Considerations | Better safety features and reduced chimney fire risk | Higher risk of chimney fires due to increased creosote buildup |

| Maintenance | Lower maintenance needs | Potentially higher maintenance needs |

| Lifespan | 15-25 years or more, depending on use and maintenance | 20 years or more, depending on the frequency of use and maintenance |

Material Durability

Insulated chimney liners are commonly made of stainless steel, while non-insulated ones often consist of clay tiles.

As a result, insulated chimney liners typically have a thicker construction compared to non-insulated liners. The added thickness provides increased durability and resistance to corrosion. Stainless steel liners are known for their strength, longevity, and ability to withstand high temperatures.

On the other hand, clay tiles, although durable, may be more susceptible to cracking and deterioration over time.

Winner: Insulated chimney liners win in terms of material durability. The use of stainless steel and the thicker design provide superior strength, longevity, and resistance to wear and tear. This ensures a longer lifespan and reduced maintenance requirements compared to non-insulated liners made of clay tiles.

Cost

The cost of a chimney liner depends on the type, size, and material. Generally speaking, insulated stainless steel chimney liners are more expensive than non-insulated clay tile liners.

For instance, a 6-inch insulated liner made of stainless steel can range anywhere from $600 to $1,000 or more. On the other hand, a 6-inch non-insulated clay tile liner may cost approximately $400 to $600.

The installation process of a non-insulated liner is often simpler and requires less manual labor, making them more cost-effective. At the same time, installing an insulated liner may involve extra materials and more complex assembly processes, which could drive up the cost.

Winner: Both non-insulated and insulated chimney liners have pros and cons, but if you’re looking for increased durability and longevity, an insulated stainless steel chimney liner is the way to go. They may cost more upfront, but they’ll save you money in the long run with reduced maintenance costs and a longer life span.

——

Do You Need to Hire Chimney & Fireplace Expert?

Get free quotes from qualified experts near you. No commitment required!

——

Heat Efficiency and Performance

Insulated chimney liners provide significantly higher heat efficiency than non-insulated ones. While the exact percentage can vary depending on factors such as the type of insulation and the specific chimney system, insulated chimney liners typically offer heat efficiency improvements of 20% to 30% or even more.

A chimney liner’s insulation layer helps minimize heat loss by creating a barrier that retains the heat within the chimney. This is especially important in colder climates or during the winter months when the temperature difference between the inside and outside of the chimney can be significant.

In contrast, non-insulated chimney liners lack this additional insulation layer, resulting in higher heat dissipation. This means that a greater amount of heat generated by the fireplace or heating appliance can escape through the chimney, decreasing efficiency and potentially wasting energy.

Winner: Insulated chimney liners emerge as the clear winner regarding heat efficiency and performance. They provide better draft improvement and enhance heat efficiency, resulting in more effective heating, improved energy utilization, and reduced risks associated with heat transfer.

Safety Considerations

Insulated chimney liners offer better protection against the risk of fire. The additional insulation layer helps to prevent excessive heat transfer to combustible materials, reducing the risk of accidental fires. It also is crucial in minimizing creosote formation, a highly flammable substance that can lead to chimney fires.

Chimney fires account for over 30% of fires annually in the U.S., according to the National Fire Protection Association. Therefore, insulated chimney liners, with their ability to reduce creosote buildup and enhance overall safety, help mitigate the risk of chimney fires.

Winner: Insulated chimney liners are the clear winner regarding safety considerations. The insulation layer acts as a protective barrier, reducing heat transfer and minimizing the risk of chimney fires caused by creosote buildup. Ensuring the safety of your home and family is paramount, making insulated chimney liners a preferable choice.

Maintenance Requirements

Different types of chimney liners may have varying maintenance requirements. Insulated chimney liners generally require less maintenance compared to non-insulated liners. The insulation layer helps reduce creosote formation, decreasing the need for frequent cleaning.

Additionally, the insulated liner’s durability and resistance to corrosion result in reduced maintenance and potential repair needs. Conversely, non-insulated liners may require frequent inspection and cleaning to prevent creosote buildup.

Winner: Insulated chimney liners win in terms of maintenance requirements. With their ability to reduce creosote buildup and greater durability, they typically require less frequent cleaning and maintenance, providing homeowners with convenience and peace of mind.

Lifespan

The average lifespan of a chimney liner can vary depending on many factors. However, chimney liners can last anywhere from 20 to 50 years or more. Insulated chimney liners typically have a longer lifespan than non-insulated liners due to the added insulation, superior durability, and corrosion resistance.

Non-insulated liners made of clay tiles may require more frequent inspections and cleaning than insulated liners. As a result, they tend to wear out sooner and have a shorter lifespan.

Winner: Insulated chimney liners are the best choice for lifespan. With their superior durability, corrosion resistance, and ability to reduce creosote buildup, they can easily last for 20 years or more. This gives you added peace of mind by knowing you don’t need to replace your liner as often as you would with a non-insulated one.

Factors to Consider When Choosing Between Insulated and Non-Insulated Chimney Liners

Choosing between insulated vs non-insulated chimney liners requires careful consideration of various factors to ensure the best fit for your needs. Here are key factors to keep in mind:

Type of Fireplace or Stove: Wood-burning, Gas, Oil, Coal

The type of heating appliance you have plays a significant role in selecting the appropriate chimney liner. Wood-burning fireplaces and stoves typically benefit from insulated chimney liners due to their higher flue gas temperatures.

Gas, oil, or coal appliances may operate at lower temperatures, making non-insulated liners a viable option. Consider the requirements of your specific heating system to ensure optimal performance and safety.

Usage Frequency

The frequency of fireplace or stove usage is another important factor. Insulated chimney liners can provide better draft efficiency, improved safety, and long-term cost savings if you use your heating appliance frequently, especially for extended periods.

Non-insulated liners may be suitable for occasional or infrequent use.

It’s also important to note that you should have your chimney liner inspected and cleaned at least once a year, according to the Chimney Safety Institute of America (CSIA). Regular maintenance helps ensure your chimney performs properly and safely throughout the years.

Durability

Insulated chimney liners are usually made from stainless steel, which is more corrosion-resistant than non-insulated liners. This can provide extra peace of mind that your liner will last many years.

On the other hand, non-insulated chimney liners may require more regular maintenance and replacement over time.

Climate and Temperature Conditions

Consider the climate and temperature conditions in your area. In colder climates, insulated chimney liners help to maintain flue gas temperatures, preventing excessive condensation and reducing the risk of creosote buildup. A non-insulated liner may be sufficient if you live in a warmer region.

Local Building Codes and Standards

Check local building codes and regulations that might influence your decision. Some jurisdictions may require insulated chimney liners. Ensure compliance with local regulations to maintain safety standards and avoid potential legal issues. Ask questions of contractors who are aware of codes that affect chimney projects.

Budget Considerations

Consider your budget when choosing between insulated and non-insulated chimney liners. Insulated liners generally have a higher upfront cost but may offer long-term savings through reduced maintenance and extended lifespan.

Non-insulated liners tend to have a lower initial cost but may require more frequent maintenance or replacement. Evaluate your budget and weigh the upfront investment against the potential long-term benefits and costs.

Considering these factors, you can make an informed decision when selecting between insulated and non-insulated chimney liners. Remember to prioritize safety, performance, and the long-term value provided by the chosen chimney liner for your specific heating system and circumstances.

——

Do You Need to Hire Chimney & Fireplace Expert?

Get free quotes from qualified experts near you. No commitment required!

——

Consulting a Chimney Professional

When considering installing or replacing a chimney liner, seeking professional advice is crucial to ensure the best decision. Here’s why consulting a chimney professional is important:

Importance of Professional Advice

A chimney professional possesses the knowledge and expertise to assess your specific chimney system and provide personalized recommendations. They can evaluate factors such as the type of fireplace or stove, usage frequency, climate conditions, local regulations, and budget constraints. They can also talk to you about a potential warranty and other details.

Their guidance ensures you make an informed decision tailored to your needs, improving safety, efficiency, and longevity.

Proper Maintenance and Chimney Fires

Chimney fires pose a significant risk to homes and occupants. However, proper maintenance can help reduce this risk. Regular cleaning and inspections by a chimney professional ensure the removal of creosote buildup and the identification of potential issues or hazards.

According to industry studies, proper maintenance can reduce creosote buildup in your chimney and decrease fire risks. By consulting a chimney professional, you can access their expertise in maintaining and preserving your chimney system’s good condition and safety.

In summary, consulting a chimney professional is crucial when deciding between insulated and non-insulated liners. Their guidance helps you make an informed decision based on your specific needs and circumstances. Contact a pro for quotes and more information.

The Winner

The choice between insulated vs non-insulated chimney liners depends on individual circumstances and priorities. However, we can provide some recommendations based on common buyer types and considerations:

- Insulated chimney liners are the best choice if you’re looking for optimal heat efficiency, enhanced performance, and superior safety features. They provide better draft improvement, increased efficiency, and reduced risk of chimney fires.

- For those on a tighter budget or with occasional fireplace or stove usage, non-insulated chimney liners may be a suitable option. They offer lower upfront costs and can serve adequately for less frequent use.

- We recommend installing insulated chimney liners if you live in colder climates or areas with higher usage frequency. They help maintain flue gas temperatures, preventing condensation and creosote buildup and reducing the risk of chimney fires.

Contact us for tailored expert advice if you need help deciding on the best chimney liner for your home or stove. We are dedicated to providing high-quality products and services for a safe and efficient chimney system.